Inventory Management Fundamentals Explained

Wiki Article

The Single Strategy To Use For Inventory Management

Table of ContentsFascination About Inventory ManagementFacts About Inventory Management UncoveredThe smart Trick of Inventory Management That Nobody is DiscussingNot known Facts About Inventory ManagementThe Best Strategy To Use For Inventory Management

The routine inventory system is a technique of stock assessment for financial coverage objectives in which a physical count of the supply is executed at specific intervals. This audit method takes stock at the beginning of a period, adds brand-new inventory acquisitions throughout the period and also subtracts ending inventory to acquire the price of items marketed (COGS).They can link a number of information factors to the number, including the supplier, product dimensions, weight, and also also variable information, such as how several are in supply. RFID or radio regularity recognition is a system that wirelessly transmits the identification of a product in the kind of an one-of-a-kind serial number to track items and give in-depth product details.

The Best Guide To Inventory Management

Supply administration refers to the procedure of saving, getting, as well as selling of products and also services. One of the most vital aspects of stock monitoring is taking care of the circulation of raw products from their procurement to complete products.For example, an oil depot can save a huge supply for a long time. Or for companies that handle perishable items, such as fast-fashion products, continuing top of your stock can be extremely pricey. One method to make up inventory is by grouping it into four classifications: first-in-first-out, last-in-first-out, weighted-average, as well as first-in-first-out.

Depending upon the kind of company that it is managing, various inventory administration techniques are used. A few of these include JIT, product need planning, and also days sales of inventory. Other methods of evaluating inventory can additionally be utilized depending upon nationwide as well as regional guidelines. For instance, the SEC calls for public business to report the existence of a so-called LIFO get.

Some Known Factual Statements About Inventory Management

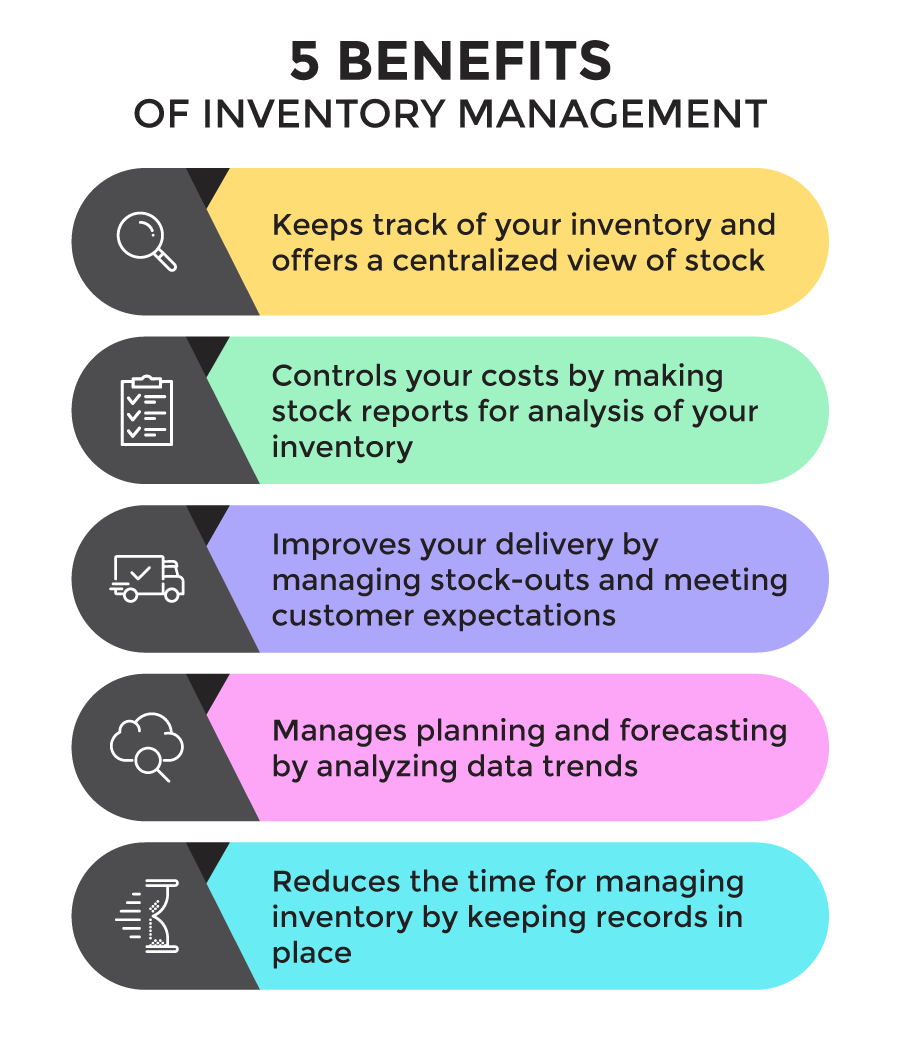

Learn even a lot more about supply management from Walton University's Supply Chain Administration program's intro on the subject covering everything from forecasting to direct designs: Among one of the most beneficial possessions of a business is its inventory. Inventory Management. In various industries, such as retail, food services, and manufacturing, an absence of supply can have harmful results.It can be vulnerable to theft, damages, and spoilage. Having a huge inventory can additionally lead to a reduction in sales. Both for local business as well as big corporations, having a correct inventory administration system is really important for any type of organization. It can help you keep an eye on all your supplies as well as figure out the precise costs.

This is particularly crucial for brand names seeking to come to be an extra customer-centric organization. Stabilizing the risks of overstocks and also shortages is a particularly challenging process for companies with complicated supply chains. A company's inventory is usually a present asset that it plans to offer important source within a year. Inventory Management. you can check here It has to be determined and counted regularly to be considered a current possession.

Some Known Factual Statements About Inventory Management

Not only will it serve to boost efficiency, yet it's also useful for preventing burglary with the aid of product monitoring as well as safety and security. Supervisors can also aim to use their stock monitoring strategy to keep an eye on sales treatments which leads to better service.:max_bytes(150000):strip_icc()/inventory-management-8595e839c2884128997ca77f00a8da2b.jpg)

Providing consumers numerous different sorts of internationally-grown produce in both natural as well as non-organic ranges at a cost effective rate, also when the fruits and also veggies aren't in period, is a modern marvel thanks partially to stock management. Looking after supply in real time as well as even establishing automated replenishment systems is mission-critical to numerous.

The Of Inventory Management

6 million bundles from their brand to third-party vendors per day. Their Smart Storehouse uses robot and human assistance to get the work done, however it's stock administration that maintains all of it rolling. According to Technology Vision, "Amazon's management strategy, together with all that automation, visit homepage have made business astonishingly lean as well as suggest by historical standards." The supply administration of bathroom paper companies remained in the spot in very early 2020 as panic-buying led to shortages nationwide.

Below are the main kinds you should recognize: Raw products, This describes pieces of your item that requirement to be delivered to you and assembled by your team. Inventory systems that track these should make up vendor timelines. Underway, Products made from resources and also are currently being constructed or grouped loss under this classification.

Report this wiki page